Getting My Sheroz Earthworks To Work

Getting My Sheroz Earthworks To Work

Blog Article

Not known Incorrect Statements About Sheroz Earthworks

Table of ContentsSheroz Earthworks Fundamentals ExplainedSome Known Factual Statements About Sheroz Earthworks Everything about Sheroz EarthworksThe Only Guide for Sheroz EarthworksSheroz Earthworks - An OverviewThe Ultimate Guide To Sheroz Earthworks

Today, Smart Building Remote links over 700 makers on jobsites to offices, conserving hundreds of hours formerly invested by jobsite managers, land surveyors and designers commuting from workplaces to jobsites. So to sum up, the very first one decade of Komatsu's smart device control have actually been marked by a decade of distinct development, constant understanding and growth with customers.

Here's to the next 10 years! Material generated in organization with Komatsu.

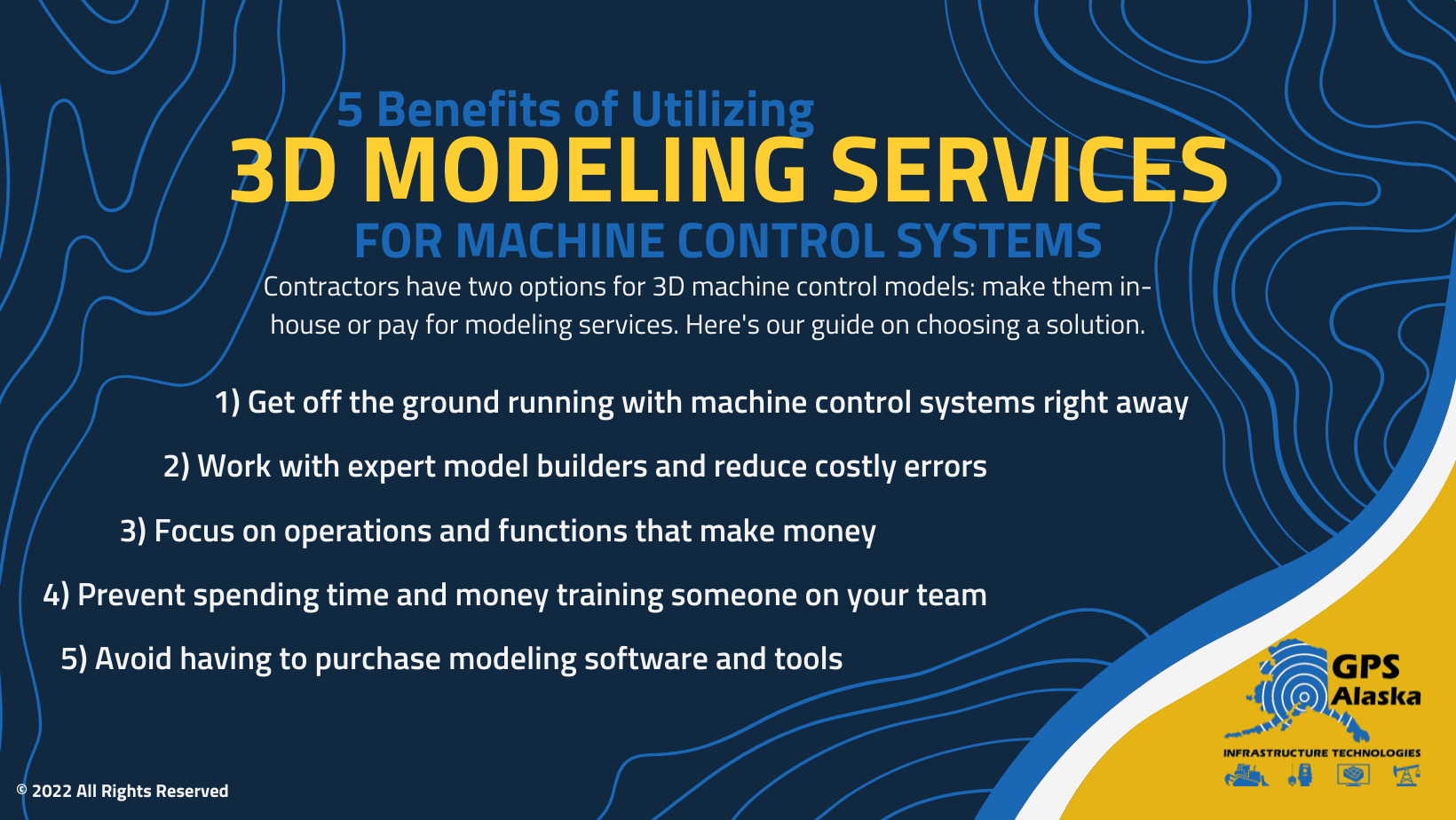

In the quickly progressing world of building and construction, precision and performance are essential. 3D machine control, a system that makes use of general practitioner and various other sensors to lead equipment with identify precision, is changing the sector - https://zenwriting.net/sherozau/sheroz-earthworks-pty-ltd-and-sheroz-hire-pty-ltd-est. From its early days of 2D guidance, this innovation has actually advanced dramatically, making jobs that as soon as called for hands-on intervention now possible with minimal human input

In building and construction, it makes certain that every cut, fill, and grade is implemented with medical precision. Allow's check out how this game-changing technology works. At the core of any kind of 3D maker control system are GNSS receivers and antennas, capturing satellite signals to establish the maker's exact location. Onboard computers and control boxes process this data and interact with the equipment.

The Best Strategy To Use For Sheroz Earthworks

This consists of establishing up GNSS receivers, calibrating sensing units, and setting up the maker control software - trimble tripod parts. The magic of 3D equipment control exists in its real-time data collection and processing.

Individual user interfaces provide real-time updates on the equipment's position and necessary modifications, ensuring exact control. In building, 3D maker control is utilized for earthmoving, grading, paving, and excavation, making certain jobs are completed to precise specifications.

Sheroz Earthworks Things To Know Before You Get This

3D machine control significantly increases effectiveness by reducing rework and reducing material wastefulness, bring about faster and a lot more cost-effective task conclusion. The modern technology makes sure every job is performed exactly as prepared, causing continually high-quality work. One of one of the most engaging benefits of 3D equipment control is the substantial price savings it uses.

Fuel consumption is optimized because makers operate much more successfully and stay clear of unneeded activities. By decreasing human error and restricting exposure to hazardous atmospheres, 3D maker control boosts worker safety and reduces mishaps.

From construction to mining, this modern technology guarantees jobs are implemented accurately and securely, reducing prices and boosting outcomes. As improvements proceed, the potential for 3D machine control to further boost performance and safety and security grows. Accepting this innovation is necessary for sector specialists looking to stay competitive and accomplish the highest standards in their tasks.

The Sheroz Earthworks Statements

Discover the future of precision and efficiency currently! Also, check out our latest YouTube video clip on the FJD H36 browse around here Motor Grader Control System to see the technology at work: Watch now.

For many years, we have actually seen drivers with lots of experience do some outstanding points with their machines. Perhaps they have an eye for modifications that improve precision, or possibly they recognize which features of their maker to make use of and when to enhance productivity or efficiency - https://www.bark.com/en/au/company/sheroz-earthworks/370va/. With today's developments in hefty tools innovation, also competent operators can profit from a real-time aid to enhance their day-to-day efficiency.

This is where maker control systems variable in. Some excavators come with equipment control systems that lead the operator with features to automate the excavating procedure.

The Facts About Sheroz Earthworks Uncovered

With this included precision, rework is practically gotten rid of, enabling the driver to finish the project on time and transfer to the next job. For those dealing with harmful or challenging jobsites, remote-controlled options open new chances. This outstanding add-on enables you to run an excavator from a distance in locations with unsafe substances (like in a potash mine) or poor ground conditions (like mud).

Machine control systems provide important advantages to greater than just excavator drivers. On-board considering apps for wheel loaders, as an example, are popular because numerous are so easy to make use of. On-board considering makes quick job of precise filling. If you have actually a truck can be found in with a target of 23 lots, your driver can fill their pail and dynamically evaluate itoften without also being fixed.

This suggests the operator can see the exact weight of the lots they will discard (fj dynamics autosteer review). On-board weighing supplies real-time insight right into the bucket's tons to make overloading, underloading, reweighing and waiting times a distant memory. Volvo Building and construction EquipmentIf they dump 12 loads on the very first pass, the next pail needs to weigh 11 tons

Fascination About Sheroz Earthworks

Most operations make use of an on-board weighing application to ensure that the load is precise prior to they send their trucks to the ranges, which is necessary since the scale weight is what's used for invoicing and invoicing functions. Several makers include some kind of evaluating program on their loaders. Some also have functions that allow business to keep an eye on and regulate the total loads of numerous vehicles.

Report this page